3M Model 89 Quadrant Dry Silver Printer

First Microfilm Printer to use Dry Silver Paper

Created: May 8, 2018

Last Revised: April 14, 2020

Chapter 1, General Information:

Quadrant Dry Silver Printer

Model 89, sales number 222.

This desktop machine produced 8 1/2 X 11 inch prints from Microfilm "chips" embedded into D size aperture cards onto the

original Type 770? buff colored dry silver paper.

It was spcifically designed to print from the 35mm film chip that was either 4-up imaged (where each of the

4 images filled one quadrant of the film chip area) or where the chip had only a single image centered on the chip.

The originals were probably 8 1/2 X 11 inches in size and filmed at a 16:1 reduction.

Many companies at that time used 8 1/2 X 11 inch paper for "A" size engineering drawings and for bills of material, by the way.

The biggest Microfilm customer in the Rockford Illinois 3M branch (where I worked) was Beloit corporation. They had filmed many thousands of that kind of document.

So they got one of the very first Quadrants when they became availble in

about 1965. And I was the "customer service representative" who took care of it.

To make a print the operator inserted an aperture card into the card holder, then selected the either the appropriate image quadrant

or the exactly centered single image on the chip using the machine's joy stick.

This joystick was provided with corner and center detents for locating the images. There was NO viewing screen.

Lastly the operator pushed a Print button and, in a matter of seconds, out came the print, totally dry and ready to distribute.

Chapter 2, A Problem:

The system worked pretty well for many customers, as long as the images on the microfilm were exactly correctly located.

I don't remember there being any positioning problems with the 4-up imaged cards, but all too often, when only one document was filmed, centered within

the chip, that document hadn't been centered carefullly enough.

Since the machine had no viewing screen, the operator had no way of telling whether the image was indeed centered in the system's

printable area until the print came out.

If part of the image was cut off on the print, the operator would have to guess how far to move the joystick away from the detent to correct the problem.

The reproduction department supervisors were very unhappy with this situation because not only did this repositioning and reprinting waste

the operator's time, but it wasted the dry silver paper (which was not cheap), too!

Chapter 3, A Solution for that Problem:

I could go into more detail about how these off center documents came to be that way, but that's another story.

At that time, i knew just enough about basic optics to be dangerous and, from a previous job had found a great source

for experimental materials, that I thought I could modifiy the Quadrant by adding a viewer to the existing machine without messing anything up.

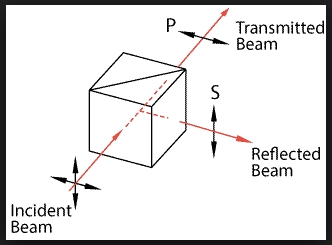

Basically, I intercepted the original light path with a beam splitter like this:,

allowing most of the exposure light to go through to the printing path, while redirecting some light upwards towards the top of the machine.

I built a viewing screen support mechanism and screen into the top of the machine, trimmed it up, and added a momentary

push button for the operator to use while centering the card.

Printing exposure times were streched a bit, but it worked out quite well.

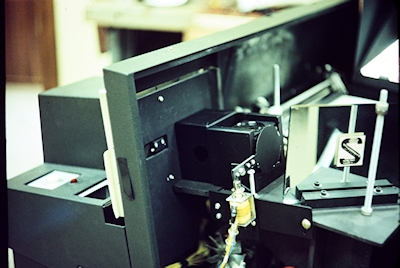

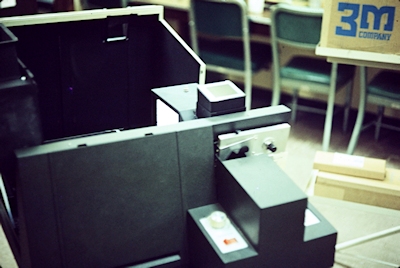

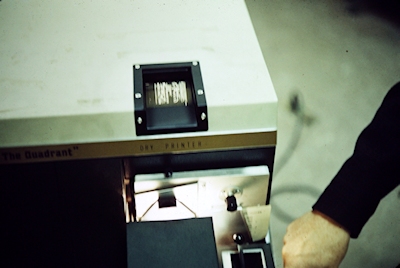

Here are a few pictures. One "before" and four "after the mod" views:

The optical system BEFORE adding the viewer:

A couple of pix of the viewer with the top cover open

And a couple more pictures, showing the operator's view of the modified system

A few months after the first one of these went into service, the Microfilm sales people from the Chicago branch heard about it.

They had a customer of their own who had an identical problem with their Quadrant.

So I built a second one. But this time I built the more robust version that you see in the pix above.

Both of those machines were still in daily production many years later.