Anvils Made From Sections of Railroad Rail

Created: December 28, 2010

French Creek Valley Home

Back to Blacksmithing

Contact Us

Introduction to Railroad Rail anvil making and design

I want to make some rail anvils to show that you don't need a huge investment to get started in blacksmithing.

Not much has been written about railroad rail anvils, but many folks have made them. Some think they are okay and others

don't think much of them at all. In this article, I am taking the positive approach about anvils made from sections

of railroad rail, so if you don't want to hear positive things about them or ideas on how to make them, don't read any

farther.

Here are some various shapes of railroad rail anvils that I have found:

About Railroad Rails and RR Anvil Design

I did some looking around on the web for design ideas, but I didn't find very much information.

I do know that railroad rail is sized by the weight in pounds per yard of length.

A Guild of Metalsmiths member who worked on the railroad for 40-some years tells me that the biggest rail in

America is (I think he said) 141#/yard. He said that rail goes up to 150# plus/yard in Europe.

Eau Claire, Wisconsin blacksmith Monte Bygd told me that he used to make them and sell them for $35. His were about a foot long, with no hardy or

pritchel hole. I think it would weigh about 15 or 18 pounds. It looks to be made from about 70# rail. He flame

cuts the horn out and grinds it to shape.

Another Guild member runs a beginning blacksmith tool making project course in Minneapolis Minnesota. As part of the

course, each student receives a rail anvil, along with other tooling that they make, as part of the project.

This anvil is about a foot long. It looks to be made from about 110# rail. They have a machine shop at the institution

where the face is milled flat to some degree and that's it. No horn at all. No hardy hole or pritchel. You can still

see the wear on the inside of the rail's ball and the burr on the outside. They sell it for $40 as part of the class.

I think this anvil might weigh 25#.

My own Railroad Rail Plans and Activities

I have been saving up pieces of rail for some years for this purpose. Recently, I cut up a 12 ft length of 74# rail

into 6 ea. 20" sections.

I have other pieces of railroad rail laying around that are about the same size rail and a few larger pieces.

None of the rail that I have is over about 120#/yard size. I wish I could get some of that 141# rail.

The best inputs I have so far for rail anvil designs are from Alexander G. Weyger's "The Modern Blacksmith" book (copyright 1974)

and the

Bernhard Heer/David Harries book "Basic Blacksmithing" (copyright 1993).

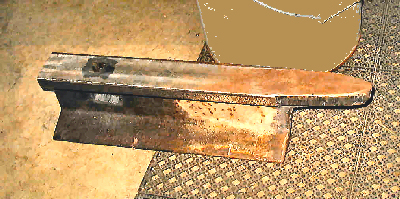

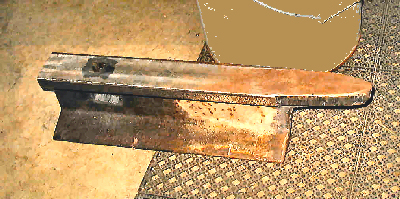

A year or two ago, I flame cut out one anvil to the Heer/Harries design and one to the Weyger's design.

The Heer anvil is 74#/yard rail X 20" and the Weygers design is 108#/yard rail X 21".

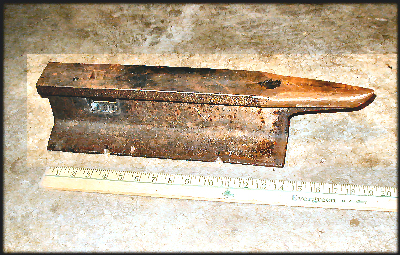

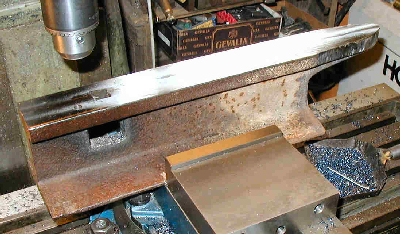

The Weyger's Design, Flame Cut to Rough Shape. It weighs 48 pounds at this point.

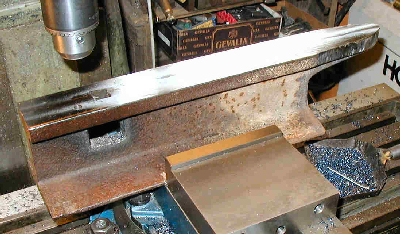

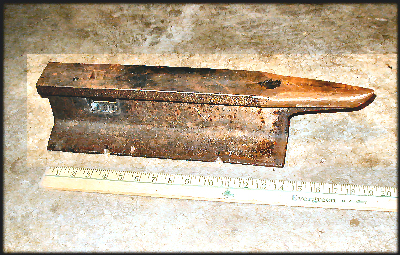

So far, I have been working mostly on the Heer design, and here are three pictures of it as it progresses:

The shape has been flame cut, the face has been milled and the hardy hole has been drilled and filed. I had no

trouble milling the face. Drilling the holes for the hardy hole was okay until I reached the exiting end of the hole.

The cast part of the rail that had not been machined was very hard and it dulled a couple of drill bits.

Here the Pritchel hole has been drilled. Same problem with tough drilling as the bit exited the hole, but I did get the

job done.

If you look carefully, you can see that I have spent some time grinding the horn to rough shape. I haven't yet decided

whether to fill in the underside of the horn with weld or not. It weighs 29 pounds at this point. I feel that this anvil

is at the lowest end of the weight spectrum for doing any useful blacksmithing.

Some Metalurgical Specs on Railroad Rail:

I got this from wikipedia rail profile:

"The American Railway Engineering Association (AREA) and the American Society for Testing Materials (ASTM) specified

carbon, manganese, silicon and phosphorus content for steel rails. Tensile strength increases with carbon content,

while ductility decreases. AREA and ASTM specified 0.55 to 0.77 percent carbon in 70-to-90-pound-per-yard

(35 to 45 kg/m) rail, 0.67 to 0.80 percent in rail weights from 90 to 120 pounds per yard (45 to 60 kg/m),

and 0.69 to 0.82 percent for heavier rails. Manganese increases strength and resistance to abrasion.

AREA and ASTM specified 0.6 to 0.9 percent manganese in 70 to 90 pound rail and 0.7 to 1 percent in heavier

rails. Silicon improves steel by increasing density. AREA and ASTM specified 0.1 to 0.23 percent silicon.

Phosphorus and sulfur are impurities causing brittle rail with reduced impact-resistance. AREA and ASTM

specified maximum phosphorus concentration of 0.04 percent."

Is there any disagreement with that?

Miscellaneous Stuff about Railroad Rail

Interesting to me:

I got 6 cuts with one Doall Imperial 100 band saw blade in used 88# (or so) rail before it started

to go dull. I'd guess that means that those rails are NOT fully hardened when they leave the mfr and they don't

work harden to the point where they are fully hard by the time they are removed from service.

Why do I have that much rail laying around?

It's the left over from my son's 39 foot high Tyranosaurus Rex. He used 2 18 foot lengths to reinforce the legs.

That's all for now. I will add to this page as I find time to work on these railroad rail anvils some more.