October 20, 2015 Iron Smelt at Tunnel Mill

Created: October 20, 2015

Last Revised: April 20, 2020

French Creek Valley Home

Back to Blacksmithing

Contact Us

Introduction:

This is the latest of 3 iron ore smelts that we have done at Tunnel Mill

(www.tunnelmillcrafts.com).

It is a more or less sequential record of how this smelt proceeded, but it isn't exactly a "how-to" lesson. Here are some useful links for anyone interested in trying one of these smelts:

Our 2012 Smelt:

http://www.spaco.org/Blacksmithing/TMSmelt2012/TunnelMillSmelt2012.htm

Our task list for a smelt is here:

TBD

Post smelt notes for this 2015 smelt are here:

TBD

Randy Purchase's photo essay:

TBD

Lee Sauder's website:

www.leesauder.com

The whole thing went very well and the weather cooperated superbly.

We got about 7 pounds of high quality bloom that needed hardly any consolidation. We also got about another 4 pounds

of material that we think we can work with sometime in the future.

According to Lee Sauder's method, we should have gotten about twice a much iron, but we are in contact with Lee to figure out

how to improve our output next season.

The furnace stood up very well and we think we can follow Lee's repair directions to get at least one more run from it.

All in all, though, we were very happy with the results.

Chunks of Cooled hardened Slag

The Smelt Site while the Furnace is being Cured

The Furnace in operation

Bar of wrought Iron we made with Ore in the foreground

Slag Tapping

Testing Carbon Content of the Wrought Iron

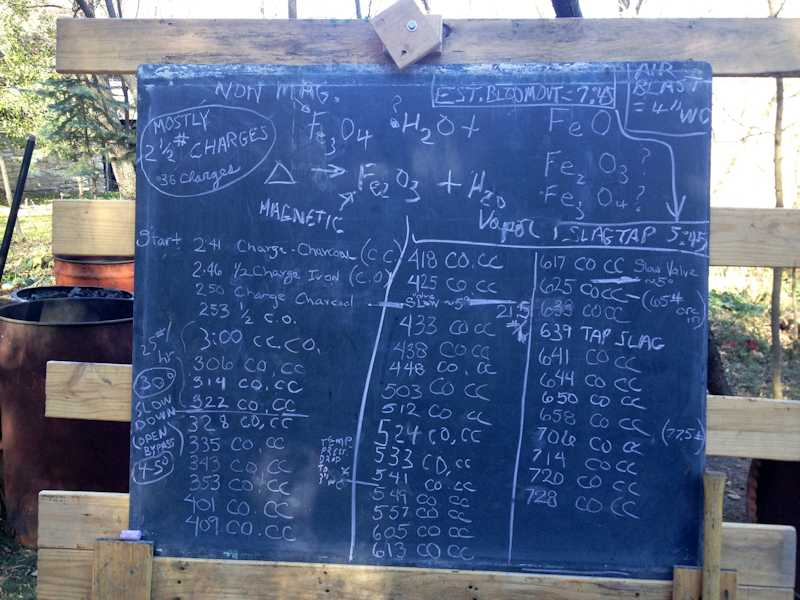

Record of the Smelting Data

The Copper Tuyere (There's a removable Sight Glass at the other end)