3M Graphic Systems and Hardware, Historical Anecdotes

Sent to me and lightly edited

Last Revised: March 28, 2024

Back to 3M Graphic Systems Hardware

French Creek Valley Home

Blacksmithing

Contact Us

Graphic Systems in general

Some recollections about the 3M Graphic Systems Group, its products and organizations:

I think BPSI (3M Business Products Sales Incorporated) was always a subsidiary. It was dissolved in the early 80s, with the formation of Equipment Service

and Support

Division (ESSD), and the operating divisions of Copying, Microfilm, BusCom, and Visuals (Background Music came along sometime in there).

But you may be right that BPSI became BPSD, as I do know that Copying, Microfilm and Bus Com were all later downgraded from division status to Departments.

And I was in charge of all that mess, and had to recruit Dale Stull to take over Copying Products Department, when he was already at that level.

Actually, Al Huber convinced him to do it.

In 1985 or so, the deal was struck with Lanier to divest Copying and facsimile via joint venture. After that, 3M was left with Micrographics, including COM,

and Trendcom, which we shut down, And there was Code 3 (medical imaging software company in Salt Lake City) which we transferred to Medical Products Division.

Visual Products became part of Gary Pint's group which moved to Austin, TX. Background Music also became sort of independent during this time.

When I went to Human Resources in 1987, all that was left was Micrographics, although it may have still been divided between File Management and Engineering

Systems (Clair Sceli ran File Management, and Bob Bright ran Engineering. (The dates are all running together in my mind though, Pete.

The additional products that ESSD took on to service mostly came about during that mid-eighties period:

Printing,

Medical Imaging,

Packaging Systems, etc.

(A good source of info during this period is Al Roux, who was the NTSM for many of those. (phone: 651-452-2723)

Some of the early copying/duplicating machines:

Since I was hired in 1958 specifically to service copying machines for the Duplicating Products Division, I have most knowledge about those, but that foggy

memory is getting in the way. The first (infrared copying) machine was the Model 11, a Console machine which was basically a prototype and not many were sold.

It was followed quickly by the Model 12 in 1955.

The next machine was the Model 17 Thermo-fax Desktop Copier. It used a carrier belt to transport the original and copy paper "sandwich" past an infra-red lamp,

with darkness determined by the speed of the belt. There were two models, the 17H and 17J, with the latter having a better speed control.

The Model 19 was a flat-bed book copier, although it was still a desk-top machine.

It was introduced about the same time as the Model 20, also called the Fourteen, which was a wide mouth copier for engineering applications, a 220 volt machine.

The successor to the Model 20 was the Model 50, which did the same thing.

The Model 21 was an automatic duplicator using A&B paper---this was the predecessor of the Model 31 Encore. These machines were the first attempt to compete

with duplicators, where one prepared a master by typing and then made multiple copies of it. They were not technically copiers.

The Model 22 Secretary was the modernized version of the Model 17, and the machine that really knocked the cover off the ball sales-wise. It evolved through

several versions and was then replaced by the Model 44 with a temperature gauge.

The Model 26 was the first attempt to make copies from colored originals which the Thermo-Fax process couldn't copy because the image wouldn't absorb

infra-red energy.

This big machine used a lamp that flashed to literally blast the image from the original to the receptor paper. It wasn't very successful, and a limited

number were made. However, the lab that developed the Model 26, run by Dr. Emil Grieshaber, assisted by Roger Appledorn, later developed the beginnings

of the Visual Systems business, and my memory is that the idea of transferring an image from an original to a piece of clear plastic came from the Model 26 work.

As you noted, the next version of the Thermo-Fax Secretary was the Model 45, a handsome, faster more accurate copier. A modification was the Model 47,

which was a statement copier, designed for applications where doctors and others used the copier to send bills to their clients each month.

During this time, lab teams were frantically trying to find a way to make copies on white paper with a bond-like feel. The Dry Photo or Dual Spectrum

process was an early answer.

This 2 step process required imaging an intermediate sheet and then transferring the image to a piece of white bond-like paper,

which was also a coated sheet. You noted that the first version, the Model 48, used the Secretary Copier to transfer the image from the intermediate

to the white paper. After that, a developer was produced, the Model 64, to do the heat imaging, but it was quite cumbersome.

Shortly later, one team developed an automatic copier to use the dual spectrum process. It was the Model 57, also called the 209 Copier.

At the same time, a desktop manual machine, the Model 76, also called the 107 was developed. Both machines required the two step process of transferring

the image from an original to the "A" paper (pink in color), and then heat transferring the image from the "A" paper to the white "B" receptor paper.

In the case of the Model 57, the A paper came on a roll which was imaged on a flat bed window, and the paper would then advance below to be matched up

with a piece of B paper which was fed from a sheet feeder and the two were pressed together against a hot pan. The final copy was then delivered into an

output tray and the pink intermediate was rewound a bit to be ready for the next original. This very complex process required a lot of service, and the

training required to teach service techs to handle it was the origin of St. Paul based training.

Meanwhile the lab had not given up on developing a duplicator to print on plain paper. The Model 74 was a large console machine which would make multiple

copies of an original typed or prepared on A paper, with the image transferred to plain bond paper and leaving a sticky image, to which toner powder

would adhere. Heat was used to fuse the image. I don't remember the specs, but it would produce about 20 copies a minute. The product was called the

A-09 because it integrated the process of "adherography".

Someplace in the 60s and 70s, the model numbering sequence was abandoned, so especially in Copying, the model numbers came out of nowhere. You correctly

listed the Model 191 as the VQC copier and yes, there were several in the series that used crush roll technology. I believe that at least one was

manufactured in 3M Germany.

The Model 235 VHS Copier was a major investment in a technology to compete with Xerox and produce a fast copier that printed on plain bond paper

using fused toner. Quite a number were placed in big important accounts, but reliability was a constant issue. You mentioned a VHS-R Copier,

but I have no recollection of that one.

I don't believe the 6740 (Van Dyk) copier was ever actually sold…again a desperate attempt to compete with Xerox. You also referred to the Secretary

III series, which I also don't remember.

Just a few more pieces of information:

Our first facsimile machine was a Magnavox 4-6 minute machine which we purchased and didn't modify at all.

It was a workhorse, but slow.

Our big splash was the first sub-1 minute machine, the 9600. It worked, but was a very large, expensive machine,

and all the imaging technology was being developed in Japan, so we weren't adding much value, other than a large sales and service force and a

good brand name. That business went to Harris/Lanier with the Copying divestiture in 1985.

At some point in the early 80s, I think, we acquired Trendcom, Inc in Milpitas, which developed an early email unit called the Whisper Writer.

It was a small, simple unit, but relied on a thermal imaging technology in which we printed a conductive ink from a small plastic print head and

had great difficulty consistently producing it. We ultimately shut down that business in about 1986 or so.

In Visual Products, that first projector was the Model 42.

Well, Pete, I think I just ran out of gas. I hope some of this is helpful in your quest to preserve some of the history which we all worked through and enjoyed.

Dick Lidstad

August, 2023: From Dave P., in Northbrook, Il:

I typed up some notes re my 3 years at BPSI. It surprised me how much I remembered after nearly 50 years and also how much I had forgotten.

From 1972-1974 I was a 3M BPSI CSR working out of the 500 N. Michigan offices. They started me out on the 209 thermal copier.

On my very first service call I saw that the customer had the media stored upside down and so I flipped it over before I even took off my coat.

When he came into the room I told him that his copier wasn't working because of the incorrect media orientation.

He argued that he had it right and pointed to the shelf where it was stored.

I did learn a bit about human behavior and customer relations in that job.

I was then assigned to the VHS (Very High Speed) toner based copier. Thank you Jerry Owens for hiring me and for help along the way.

I spent a couple of weeks at the St.Paul training center which was connected with a Howard Johnson's.

I then worked under the tutelage of Al Hajek. My main accounts were Illinois Bell and the Playboy Club.

Some of my co-workers were Mike Caines and Dan Kapsa and our dispatcher was Mike Murphey.

Though it was quite a commute for me from Evergreen Park I loved working Downtown.

The lake, the museums and especially the camera shops were all quite a draw for me.

Every month the sales team treated us to an evening at The Millionaires Club.

I was also one of the "Mighty Mickies" a long haired bowling team sponsored by BPSI who bowled at Diversey River Bowl.

Our long sleeve western style shirts were decorated with the image of a mouse head that had been printed with the 3M color copier.

I left in ' 75 for a tech position at Argonne National Lab in Lemont that lasted 47 years but my memories at BPSI are something I'll always think of fondly.

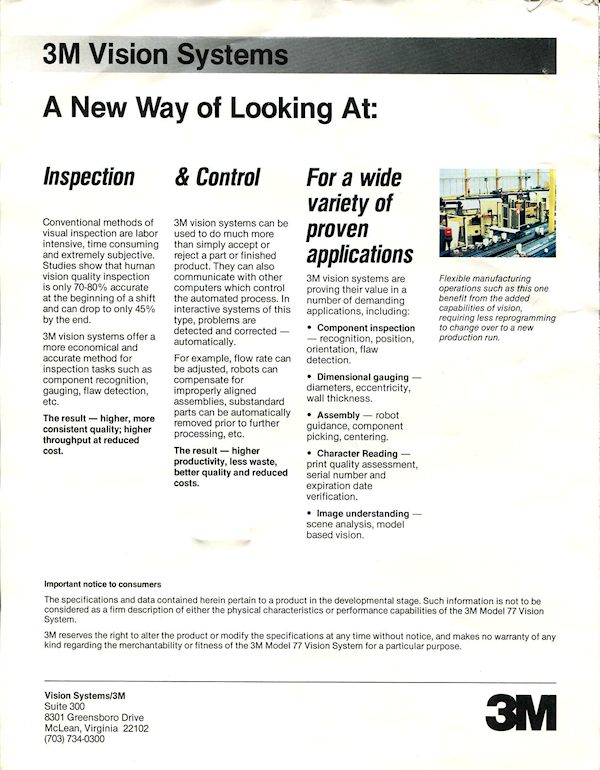

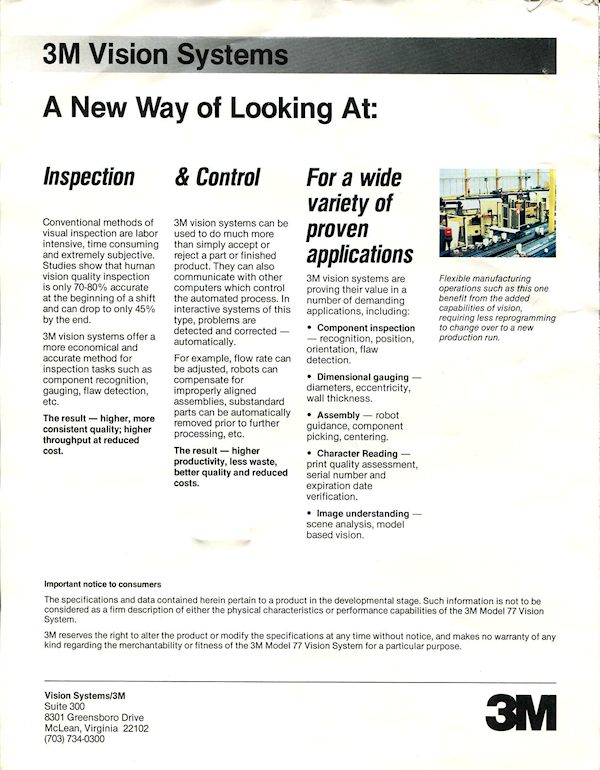

3M Vision System

Hi Pete. Been looking in old stuff. It looks like I've tossed almost all my 3M related work files regarding model numbers. I did find this:

It's a project that I was assigned to by George Croop in the mid 80s.

This team in DC wanted a tech rep for the northeast. I spent a few months with them learning this, but they weren't selling any.

It was really behind the tech curve and the salesmen quit. So they wanted the tech reps to start trying to sell it. After getting laughed

at the first few sales calls, I asked off the program. I did learn a lot about digital imaging that has served me well.

CU

bill

Notes about some of the later (Non Thermofax) copiers

The "609" was a high speed dual spectrum machine that was essentially the "209" on steroids. But it didn't do a thing for the high cost of dual spectrum.

The "VHS" was indeed 3M's plain paper copier, but it was large and ungainly.

The "VQC" line (Model 191, 207,383, 483, etc.) was internally developed but in some sort of partnership with Toshiba.

This "VQC" line used a magnetic drum and corresponding dry ink particles to image on "plain" paper, which was then passed through

the pressure rollers to fuse the ink to the receptor. The paper was legally "plain",

but it was made to an exacting specification for surface topology, weight, and stress integrity.

Users who tried off-the-shelf plain paper found out how narrow the operating margins of the technology were.

-Mark.

Some general machine notes from Phil, CSR (Customer Service Representative) from Chicago:

Pete, I worked as a CSR at 3M BPSI in Chicago from 1972 to 1987 when Harris/3M was formed.

I serviced many of the products you have listed. The 191 copier was mostly a Toshiba "Engine", with

3M"s dry toner process replacing the Toshiba "wet" process. The 191 used a heated cylinder with a

"fuser blanket" wrapped around the outside which had to be replaced after about 10k copies were run.

Subsequent VQC models used the crush rollers.

The 787 was the first 3M copier with "self diagnostics".

The 848/858 were the last "all 3M" designed copiers; the 858 was the first "talking" copier.

Subsequent copiers were supplied by "Copyer"(Canon), Toshiba, Sharp, Kodak, and Van Dyk.

3M made some of the early fax machines such as the 711 and later Oki supplied most subsequent ones.

3M dry silver microfilm reader-printers were all made by 3M.

Once "plain paper technology" became common, 3M spun off most of its imaging products to dealers such as Lanier.

Phil Oellrich, Chicago, remembers the Color in Color copier

In 1972 I was a CSR working out of the 3M BPSI office at 500 n Michigan Ave, in Chicago.

We had a street-level store open to the public that had a Color-In-Color machine. Alan Yeager and Jim Ludlow were the CSR's who were trained on it.

I remember the C-I-C used 3 rolls of color intermediate paper to print with, and it took over one minute(maybe three) to make one print.

The C-I-C could make heat-transferable prints on fabric such as t-shirts. The C-I-C was used by textile companies to print different colors of fabric samples,

saving the textile companies from having to weave each sample in different colors.

I remember there were a total of 3 C-I-C machines in Chicago, and their lifespan was fairly short.

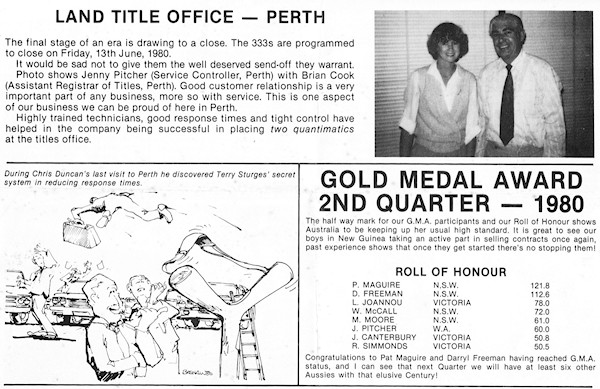

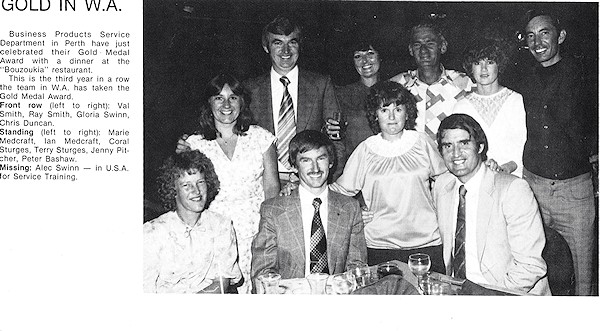

3M Australia, notes by Peter Bashaw

Peter contacted me in October of 2015, asking if he could help add to our 3M worldwide picture.

Here is his reply:

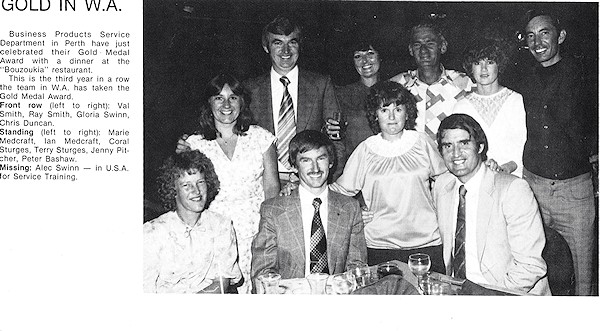

3M PERTH photo date, early 80s, I'm second from the left... Model 17 is a unknown to me, I was a copier man.

The Microfilm Tech is the man to the right of JENNY PITCHER our service controller, on far right, is Alec Swinn, the

book detect, fax mach specialist.

OHP, and THERMO FAX were in schools everywhere

Only one head office, no independent dealers, for each state, (I was) Employed from 1973 to 1986.

The 777 was on branch trial only.

The 191 was very much in use till cold fusion model 275s pretty much replaced them as they were good sellers.

and Toshiba Plain paper copier models followed these.

Extensive book detection installations were also popular, but slow fax sales because of phone line reliability ,

(good storeys about sending fax service reports from remote hotel locations via switchboard operators}.

I took photos for head office in SYDNEY of Govt book detect installations we made in West Aust.. you may have interest in them.

I still have a contact with the service manager as we were a tight team and I include the whole branch, from sales dept to

shipping dept... anything more I can add please ask.

Thank you for showing interest.

Another look, West Australia:

Photos I took of first operating book detect system in West Aust. It was a video cassette rental shop and the second was

the Kalgoorlie College Library When the job was done, Alec and I would spend a few days gold prospecting before we

retuned to Perth.

Editor note: I don't have enough "Safety and Security" (Library Systems) info to put up a separate page.

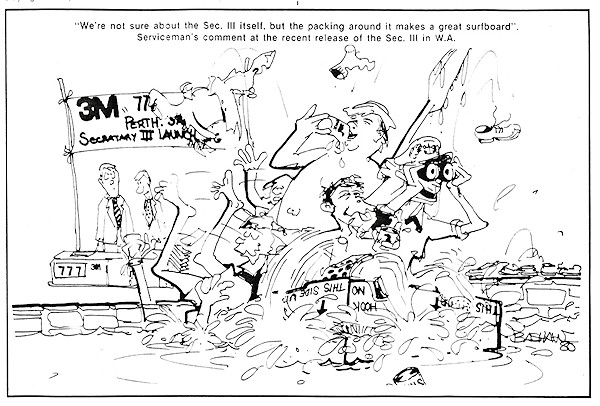

Third look from Peter Bashaw, Perth:

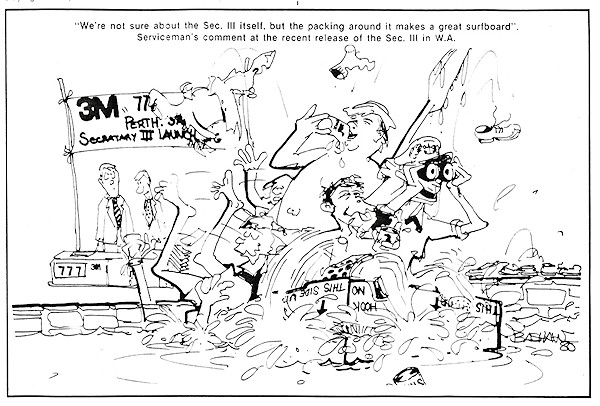

And more pix of the Perth office and of Peter's art:

This was our location in PERTH in my time so with these I am tapped out until I hear from others with new material.

After the downsize I went on to work with CANON for another 8 years, then RICOH for one, by then service was headed for extinction.

From there, surprise surprise, I became a illustrator.

Today I do volunteer work at our local art gallery setting up exhibitions and display some of my own work.

Thanks for the chance to air the novelty items I kept of those times:

I had great fun doing those news sheets at 3M along with the great people,

from the shipping room, sales, office staff, receptionist

and management, never equaled anywhere else from those days.

I enjoyed sharing those times with you.

Sincerely,

PETER BASHAW

Notes from Paul, New Haven Ct., about some later Microfilm Division equipment:

I recall the Micrapoint 1 and Micrapoint 2 that I supported. At that time I was considered the product expert in my area

as I probably had 12 systems in my area.

Models 381 and 382 respectively. This was before the days of the PC

They were basically large desktop mini-computers, with two 8 inch floppy drives, single sided, later double sided,

a monochrome monitor, 256K memory max. I think they were made by Pertec?

They had software that would interface with 3M page search reader printers. All the Micrapoint did was index a name,

or policy number, or whatever info the customer wanted to input from the microfilmed page displayed on the reader printer.

That way, when you had to look up lets say a policy number, the Micrapoint would search it and come up with cartridge 30, page 345,

the customer would insert microfilm cartridge 30, hit search, and the reader printer would load the film and search out page 345

and there you are.

Hit the print button and you have a dry copy in 6 seconds.

There was a "PST" in between the Micrapoint and the reader printer, called the "page search terminal". I don't recall that model number.

They mostly interfaced with the 600 Reader Printer and the 900 Reader Printer. when the 7510 Reader Printer came along,

most customers had their own search terminals and software and the Micrapoint, a stand alone system, faded away.

The Micrapoint II also had an optional hard disk drive, 40MB made by Winchester with a 10MB backup tape drive,

and it was big bucks back then, the service contracts were big and the commissions that came from selling those service

contracts were pretty fat too. The size of the HD option was a cabinet about the size of a trash compactor from the 70's.

There was also another software application that was developed for the hardware called "Crimestats" made for law enforcement

but technology was changing so fast that it just fell flat.

I also serviced the "LBR", Laser Beam Recorder, and the "LFR", Laser Fiche Recorder, 9 track tape drive, what a device! Maybe more on that later.

Annual Tech Education Center Luncheons Continue

(Author: Pete Stanaitis, photo by Dave Metzler)

December 14, 2016:

Ken Stewart from the Technical Education Center again set up this annual luncheon.

We had 26 people there, as far as I can tell. The top of Ken Stewart's head is barely visible at the center rear.

Many of the people there actually retired from Imation, (and maybe Harris, too?)by the way.

3M Whisper Writer Anecdote From Moshe in Zurich Switzerland, March 2024

3M acquired the Whisper writer business at some point. A really quiet thermal printer.

We sold a bunch to a Swiss company that needed to do lots of screen dumps and couldn't allow noisy EPSON printers to disturb co workers.

This would be a nice business for 3M since they thus ordered many rolls of thermal paper - 3M loved supplies businesses.

Problem was that when the user tried to print a screen, the bottom third of the page was gibberish.

I ended taking a machine to a top tech guru in TelAviv and he guessed correctly that the 3M printer had too little buffer memory.

At his suggestion I found a company in the US that sold printer spoolers as black boxes, and got them to slap a red 3M logo on the box.

The customer ordered a bunch, and was a good customer for years for the thermal paper.

Betacom in Europe, according to Moshe R March 2024

At some point, 3M acquired a COM product (Computer output on microfilm) called Betacom which worked as follows:

A customer's computer would capture the output of some program, eg: a bank's printing monthly customer statements,

onto a reel of magnetic tape instead of sending it to the printer.

The COM machine would read the tape and produce an image of the printout on a screen,

and photograph the image onto a microfiche. (A microfiche is a postcard sized piece of film with place for a few hundred images on it

- each looking like a page of computer printing. ) Thus, on each fiche,

the customer saved tremendous storage space in case the printouts needed to be referenced at a later date.

Microfilm readers and products were a key business for 3M.

The physical COM unit was huge: think of a couple of fridges next to each other.

It had a teletypewriter as an input device, a magnetic tape reader, and was controlled by a DEC PDP-8 minicomputer running proprietary software.

When 3M bought betacomm (in 1975), there was a separate program to process each type of magnetic tape for different computer brands such as IBM, Univac, Burroughs.

The customer could only control a few parameters on how the fiche was formatted.

As the number of computer brands proliferated around 1980, the situation became untenable.

It was nearly impossible to keep rewriting the programs all the time.

3M hired a computer whiz from MIT to write a one size fits all program, that allowed the customer to define the format of the input tape,

and the format of the output fiche.

It was a masterpiece of computer programming, but was top heavy for the users due to the myriad of available options.

I helped launch it in Europe, and got to travel around to various countries both helping with pre-sales and support.

One customer- a European airline - had a brilliant idea. Why not put all the onboard technical handbooks for each aircraft onto microfiche,

and put a fiche reader on each plane?

That would save place and weight, and allow for easy updating. (Of course this was before DVDs, SD Cards or USB sticks)

Together with experts from St Paul, I travelled to McDonnell Douglas and Boeing in Long Beach and Seattle.

The aircraft builders liked the idea, but it never took off.

I fondly remember my visits to St Paul from Europe. People were so helpful and friendly and open to new ideas.

By the way, 3M had a motto that, at any given time, 25% of sales should come from products introduced in the last 5 years.

Click the links below to see the (partial for now)machine model list for the subject division:

Duplicating Products Hardware

Business Machines sold by the Microfilm Products division of 3M

Fax Machines sold and produced by Business Communicatons Products Division

Printing Products Hardware

Overhead Projection and Support Equipment of the Visual Products Division

If you'd like to contribute an article about any one of these machines, please use the contact link at the top of this page to let me know.