Ideas for Adjusting Lathe Chuck Jaws Faster

Revised: October 21, 2023

Home

My Machine Shop

Hole Tapping Tips

Blacksmithing

Contact Us

1. Quicker 4 Jaw Chuck Centering

A few months ago I saw an article in the Home Shop Machinist where a guy made a pair of tools to speed up the process

of centering the work in a 4 jaw chuck. He milled a square on the end of a bar that just fit the sockets of the chuck

screws then turned nice knurled knobs on the other end, about 1 1/2" diameter. To use them, you simply stick one into

one screw and the other one into the screw opposite. Real easy to go back and forth while making the fine centering

adjustments.

The "fast" part of this is that you don't have to go back and forth with the single tee handle as you move opposing jaws.

Great job, I thought.

I noticed that the sockets on both the 3 jaw and my 4 jaw chucks on my Atlas Lather take a square that is about 0.420" on a side. I also

noticed that a piece of 3/8" square stock, although a little sloppy, works just fine for low-torque adjustments.

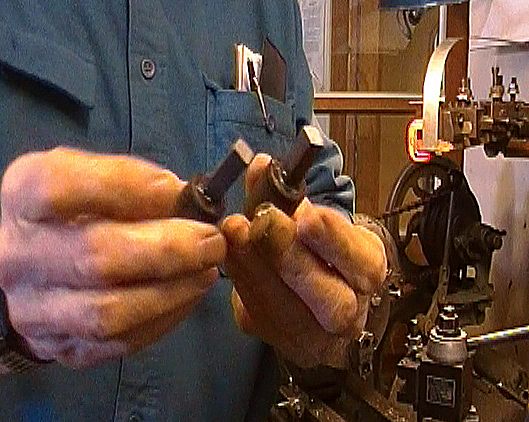

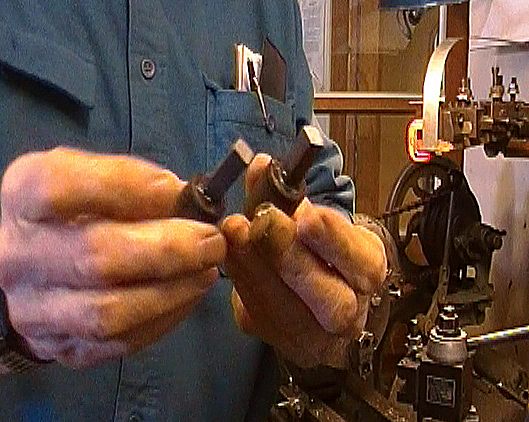

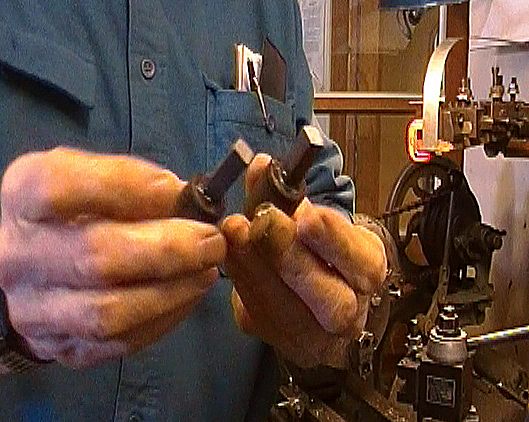

I picked out the two largest extra 3/8" drive sockets that I had laying around, cut off 2 pieces of 3/8"

square bar about 1 1/2" long and glued the pieces into the sockets. I simply used silicone caulk as the adhesive so I can pull them

apart if I have to.

Using a pair of these on opposite jaws works great for the centering of work in the 4 jaw chuck.

It would be nice if I had bigger sockets, but these will work until I go to the next flea market and find some those bigger ones.

2. Faster Chuck Jaw Reversing, or Making Large Chucking Diameter Changes:

Well, a couple of days ago I had to reverse the jaws in my 4 jaw chuck and was giving myself carpal tunnel (using the big

tee handle chuck wrench).

So from now on I will use this method:

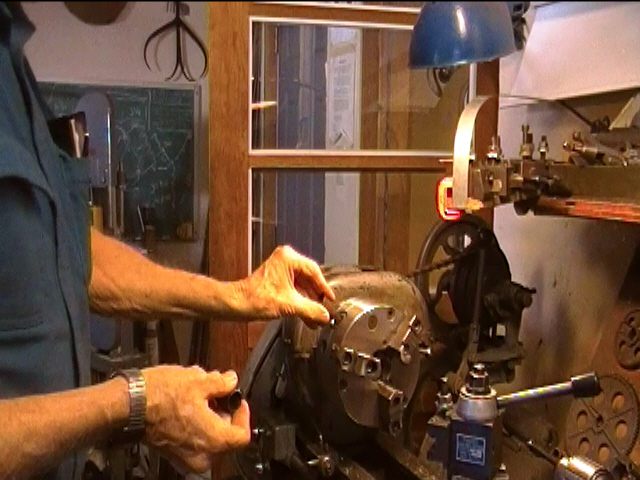

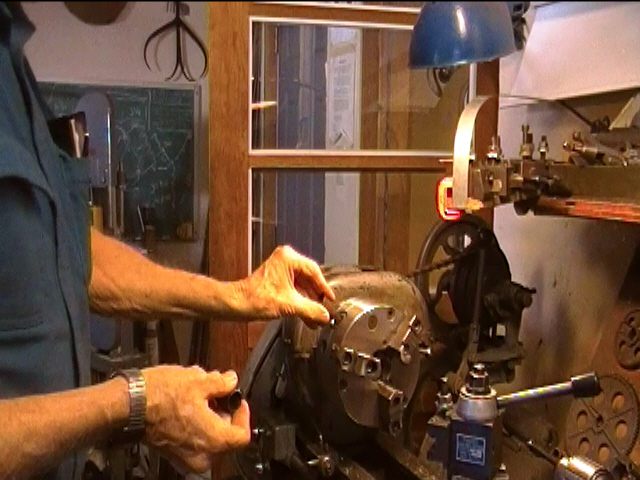

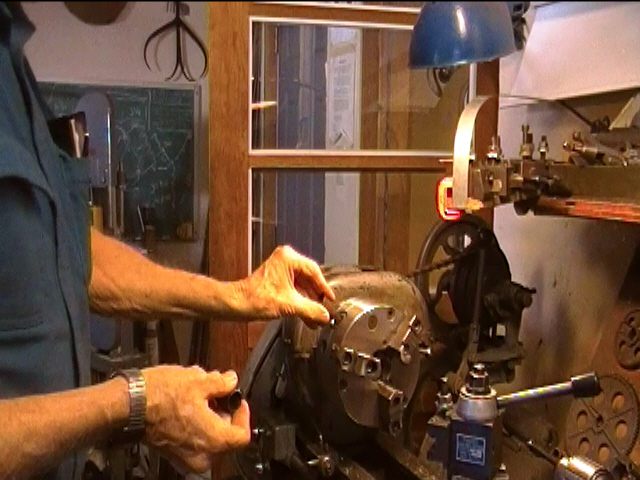

Simply use the "speed handle", the "crank" from a 3/8" drive socket set.

This is great for going long distances with the jaws or for reversing them.

I am sure that I have seen somebody who turned a round shank on a square piece of stock and stuck it into a cordless drill.

And then they used it to move chuck jaws rapidly.

Here below is my take on that tool. It's about a 2 inch length of 3/8" square stock with about 3/4 inch turned to 3/8 inch round.

Here it is in use:

I guess this would be the ultimate in "speedy lathe chuck diameter change" but it won't be my choice.