Stored in an old office "side cabinet" that has 5 drawers. One of the drawers is devoted to the "rounds' and a second drawer is dedicated to anything that is rectangular

Like most everyone else who has a shop of some sort, I have been struggling to discover "THE" perfect stock storage solution for many years and

I'm still at it.

This page simply tells where I have gotten to by now.

---Nobody said this was going to be neat.

First, I try to sort Mild steel (hot and cold rolled) from non-ferrous metals(which are sorted by type)

Then, I attempt to sort materials by cross sectional shape:

-Round

-Square

-Rectangular

-Other, including Angle, Channel, etc..

Then I sort by length.

I do this so I can, hopefully, find it easy to locate the shortest possible piece of stock for the job at hand.

Drops (Under 6" in length)

Stored in coffee cans under my central work bench

Shorts (Under 18" in length)

Stored in an old office "side cabinet" that has 5 drawers. One of the drawers is devoted to the "rounds' and a second drawer

is dedicated to anything that is rectangular

3 feet to 5 feet

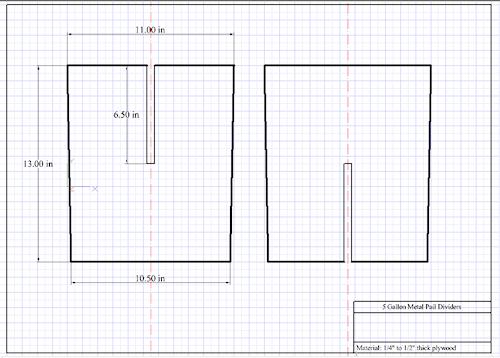

Stored standing up in 5 gallon metal pails.

Over 5 feet but less than 9 feet

Stored in a small 6-section vertical rack in the forging area

Over 9 feet but less than 12' 1"

Stored in a horizontal rack that is 2 1/2 feet high and 8 inches deep that is sandwiched in behind my lathe, trip hammer and

forge on the south wall of the machine/blacksmith shop.

Left end view

Right end view

12 feet to 17 feet and bulky

This metal was stored in an old 17 feet in diameter metal grainary that was left over from our hobby farming days. I also

stored blacksmithing coal and coke here.

But that granary blew down in a wind storm in about 2020. I have moved everything BUT the long stock into our machine shed.

I am still waiting for my sons to clear a large enough area in that shed for the long stock. So, for now, that stock rack is still sitting on the bare concrete pad,

pretty well covered with a tarp, to minimize rusting.

20 feet

Some of this material is stored in the same building where our rough sawn lumber is kept. I have simple racks along one

wall for this purpose.

Sheet and Plate Goods

These materials are stored in an unheated corner of the car garage, mostly standing up so they don't take up too much room.

Some plates that are 5/8" thick or more are stored in the grainary mentioned above.

Tool Steel

All tool steels are stored in one corner of the machine shop, vertically. This is a 1 foot by 2 1/2 foot space

behind a door, in an area that couldn't be used for anything else.

The tool steel pieces are all individually marked.

This allows me to simply stick them into the 2 five gallon pails that fit back there.

Rough sawn lumber

1st year after sawing:

I always stack and sticker freshly cut wood outside under cover for the first year.

By doing it this way, the wood gets enough ventilation that it doesn't mildew or rot where it contacts the stickers.

These stacks are just outside of our main wood storage building.

After one year of drying outside

Once the wood has begun to dry, I move it inside of our 22' X 54' wood storage building, stacked and stickered again.

Once the wood is as dry as it is going to get, I may stand the long stuff up, as vertically as I can, in that same building.

Some of this wood is moved into the wood shop, where I can handle several hundred board feet at the top of a couple of 8 foot

high sections of shelving.

I have also stored several hundred bf above the woodshop in the attic.

Planed Lumber

I usually try to store planed lumber and other finished goods inside the woodshop, although I have several hundred bf

of stock in the woodshop attic.

Sheet goods

High quality sheet goods are stored inside the woodshop, standing vertically against a wall that hasn't gotten filled

up with machinery yet.

Lower grade plywood, etc. is stored in the wood storage building or in the woodshop attic.

Short pieces that are "too good to toss"

I try to categorize this stock by length and store the pieces upright in plastic pails.