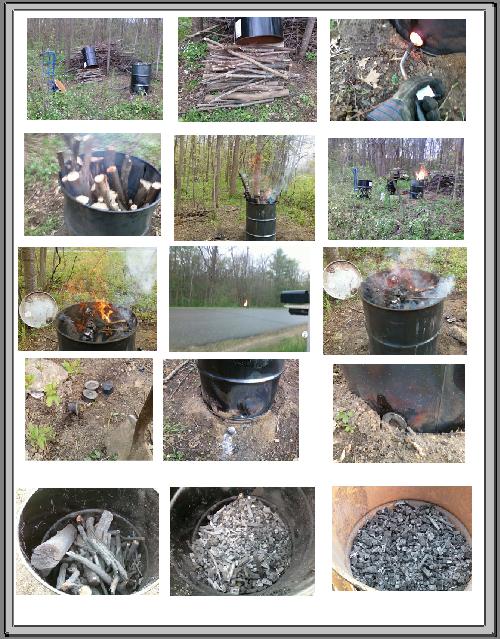

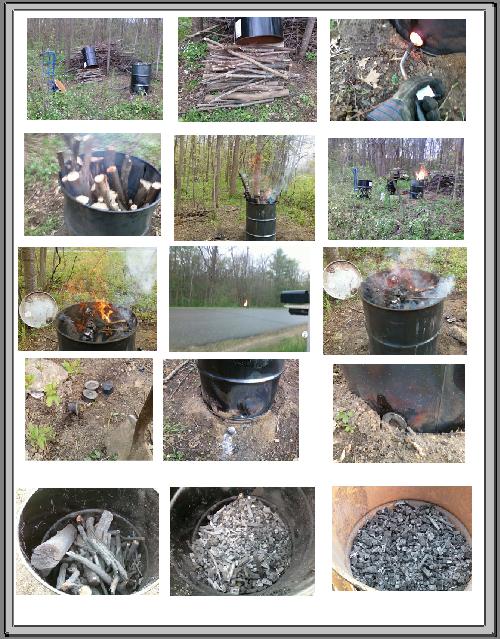

Charcoal making, as done by the Tunnel Mill group to provide fuel for smelting iron:

The Retort:

-Locate 55 gallon steel barrels with fairly tight fitting lids (rock on lid without clamping ring is okay).

-Make 4 or 5 plugs by welding an oversize washer to a short piece of round stock, maybe 1 ¼” or 1 ½” diameter

and an inch or so long.

-Drill (hole saw, I suppose) 4 or 5 holes around the base of the barrel, an inch up from the bottom for the plugs.

Loading:

-Put some paper and some small pieces of wood in the bottom of a 55 gallon drum. (maybe add a little diesel

fuel to help)

-Fill to top with wood. Don’t use any material bigger than about a 2X4. Throw it in somewhat loosely.

Then, once the fire is going well, mound wood up a foot or two above the top.

Wood Reduction Process:

-Then light thru small holes

-Let it burn for about an hour.

The goal here is to get most of the wood well charred, without losing much charcoal.

My freind John says he checks a few pieces to see if they are coming along well.

This is an "arty" part of the process.

-Put undone stuff from previous burns into the barrel about 20 minutes before putting the lid on.

-Just before putting the lid on, I usually throw in enough short pieces to fill the barrel almost to the top.

Most of this won't become charcoal, but will give that wood a good start for the next run.

-Put the Plugs into the holes at the bottom. Pile dirt around the plugs to minimize air leakage into the barrel.

-Put the lid on the barrel and seal it fairly well. Adding a clamp isn't necessary, according to John.

He simply puts a heavy rock on the lid.

------

-Wait a day before removing the charcoal.

-Remove the lid. The incompleted wood pieces are almost always on the top. I remove them from the retort

first. Then I dump the charcoal into a barrel for storage.

-John says that he gets about 2/3 barrel left as charcoal, maybe less if you didn't mound the fuel a foot

or two high earlier. John usually uses construction scraps, but I use dead branches so I can't pack the retort

as tightly as John does. So I get at least 1/3 of a barrel of charcoal from each run and often get 40% or so.

-Put the "not completely burned through and through" wood into the next load.

Comments

-When we are making iron, its, not too critical that EVERY little piece of wood be completley pyrolized, but for a

charcoal gasifier, we want to be pretty sure there isn't any volatile matter left to tar up our system.

-Before loading the charcoal into the gasifier, it needs to be classified to the optimum size for your machine.

How you do that is up to you. With the branches that I am using I don't need to do any breaking-up of my charcoal.

But I do need to screen out the "dust" which is both ash and charcoal dust.

I also try to handle my charcoal gently so I don't break it up and waste any as the "dust" that I screen out.

-One BIG advantage of using tree branches is that I don't have to worry about metal objects like nails or about rocks

and earth getting into my charcoal.