Summary of the Season and Results of my November 9, 2012 Woodchips to Electricity Test

Revised: October 21, 2023

French Creek Valley Home

Back to Our JXQ-10A Main Page

Contact Us

This is the last test I will make this year, because it is getting cold outside here in western Wisconsin. I consider it the

most successful test I have run so far.

I have run several tests so far this year, some with the gasifier hot and some with no fire. And only a couple of tests with

the Onan Genset running from the woodgas.

Some of the tests were needed to integrate my new datalogger. Once I started to get data, I needed to run more tests to start

solving the problems that keep me from running the genset for extended periods.

Info on THIS test is at the bottom of the page, after the summary of the season.

I have graphs of every run that I made, but many of them are rather complex (really, just hard to read), so I only sparingly publish them here.

Summary of tests this season:

June 19: First test of datalogger. A Hot Test, but no generator. Just getting some data on actual pressures and

temperatures. Found out that the best temperature I could get below the grate was only about 570 degrees F, far short of

the approx. 1000 degrees F that is apparently needed for tar-free gas.

June 24 & 25: Both were Cold Tests. By that, I mean that I didn't have a fire in the gasifier. In this test, I simply wanted to see how the

system behaves in "normal" mode, that is by simulating the gasifier feeding the 2 burner stove.

There were concerns that there might be blockages somewhere in the system. I didn't see any signs of that.

I needed this kind of test to get a

handle on the interactions between the various pressures throughout the system as various system restrictions occur.

I learned, for example, that having the fuel hopper door open doesn't affect the system operation at all.

It also showed me that the suction below the grate was much less than I would have imagined, usually on the order of

about -1"WC.

June 26: Another Cold test. There had been concerns that the blower might might have been slowing down during a run.

This turned out not to

be a problem. The blower speed remained very constant under all test conditions, at about 3500 rpms, and current was

stable. The case temperature of the blower stabilized at 148 degrees F (64 degrees C) after 3 hours of running.

Ambient temperature

was 81 degrees F (27 degrees C), so that's a rise of 67 degrees F (19 degrees C) which shouldn't be a problem.

I learned that I was loosing water out the standpipe and that, once I lost enough water, the regulation part of the filter

became ineffective.

Aug 14:Here I added a 3 foot extension to the standpipe to keep water from bouncing out of the filter.

I also tested to see if pressures would stay constant over a long period of time.

Since things hadn't been going well up till now, I decided to attempt to run the gasifier system EXACTLY as it

had been designed, that is: to use chopped straw as the fuel. Boy, was that a disaster!

Chopping up straw to one inch lengths, as the instructions say is a HARD job. And it takes a long time, for me, anyway.

I chopped up two tightly packed 5 gallon pails of straw for this test.

Results: The straw burned VERY fast! And I didn't get any usable gas. I have decided never to use straw again. I don't

know how a Chinese householder could get any cooking done with that stuff as fuel.

After trying the straw, I reverted to wood chips and got gas for an extended period of time.

Aug 31: Cold Engine Test, with engine sucking on the gasifier:

In this test I wanted to see how the gasifier system responds to suction from the engine. There was no fire in the

gasifier for this test. I ran with the blower on most of the time and found that I needed to close the engine's air cleaner valve

about half way to get enough suction to the grate.

At this time, I hadn't realized that when the engine is running while connected to the gasifier, it is sucking fresh air IN

from the standpipe and drain tube.

I also learned that I could max out my 7Kpa (28"WC) sensor when it is connected to the engine Tee.

Sep 1: Another Cold test with engine sucking on the gasifier.

Here I explore the idea of plugging the standpipe and the drain tube so that NO air can be sucked in to the engine

(from the gasifier) with the fuel stream.

It is finally dawning on me that IF I suck on the right chamber with the engine, I will pull the water in the bottom of

the filter up quite high into that chamber. As that water is sucked higher into the right chamber, several bad things happen:

-Think of the right chamber as a manometer. If we have, let's say, 10"WC of available suction at the top of the chamber, and

if the water level rises 6 inches, then there is only 4"WC available to be distributed over the rest of the system.

-As soon as enough water is sucked up from the bottom of the filter box to uncover the gas inlet pipe from the gasifier,

the hot, dirty gas no longer bubbles through any water, but proceeds directly to the bottom of the right hand chamber.

This means that the gas isn't filtered or cooled by the center chamber, only as it bubbles through the water column in the

right hand chamber.

If the blower is ON at the time, then some of the hot, dirty gases have to go through the blower housing to get to the

right hand chamber. This situation not only coats the blower housuing and blower wheel with tar and particles, but I coats

the whole inside of the center chamber with the various kinds of crud. BAD.

If the blower is OFF at the time, the suction on the right hand chamber will be even higher, so MOST of the hot, dirty

gas will not be processed in the center chamber. Instead, almost all of it will go directly to the right hand chamber. BAD.

-In either case, above, the gas will not be cooled at all by the heat tranfer effect of the "bottom" water to the left hand

cooling water tank. This means that the right hand tank will get a lot hotter than it otherwise would, and, consequently,

the temperature of the gas going to the engine will be hotter.

This is BAD because a hotter gas contains less fuel molecules per "gulp" of the engine's intake stroke.

Oct 17: A Hot Engine Test:

It was about 2 hours long.

The goals:

-To (finally) see what below-grate temperatures I could produce when running an engine.

-See how long I could run my genset, now that I knew I had to plug the standpipe and the overflow tube to keep from

sucking air into the gas stream.

-------------------------------------------------------------------------------

It didn't go well at all.

I got the genset to run for a total of 59 minutes during the 2 hours, in 6 sessions that lasted from 2 minutes to 20

minutes each, but with no load at all.

-After I had ended the test and was cleaning up, I discovered that I had not replaced the fiberglass filter material in the

filter compartment chamber. I had been using the same material since my June 19th test! All that was left in there

was a black, stinky, gooey, wet mass of stuff. All the "fluffiness" was gone and it was matted up in the bottom 2 inches

of the chamber.

Now I suspect that this was my major culprit for the day, making the whole run rather useless.

-During the engine running periods, the amount of engine vacuum required to keep it running gradually increased from

about -6"wc to about -18"wc. I assume this was because of the filter material becoming gooey-wetter during the run, but I

am not sure. I will need to run another test, with new material or some other sort of filter.

Oct 26: Cold Test, Testing for any Suction leakage sources.

After my last hot test, I ran a suction leakage test and (after correcting my own operator errors) found no leaks.

I had hoped that I'd find a big leak someplace that was causing my problem of poor suction at the grate.

-Conclusion: Poor suction at the grate isn't really "poor suction"! The fuel bed simply doesn't restrict the air/gas

flow very much at all! I need to Pack the fuel bed much more firmly than I have been doing.

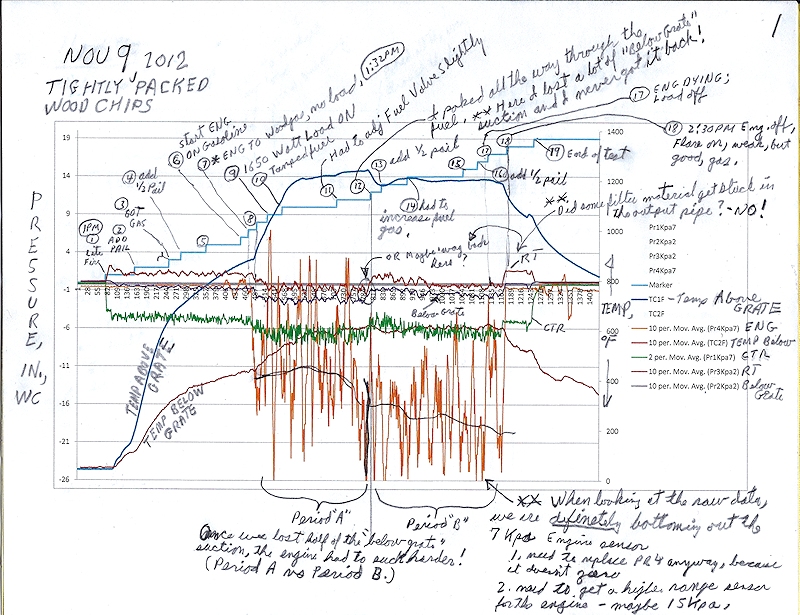

Nov 9: Hot Test with engine

This was my best test so far this year. I ran the engine with moderate load (engine plus 1650 watts of electrical load)

for about 52 minutes. The test ended abruptly for some unknown reason, but my best guess is that I ran out of water in

the bottom chamber.

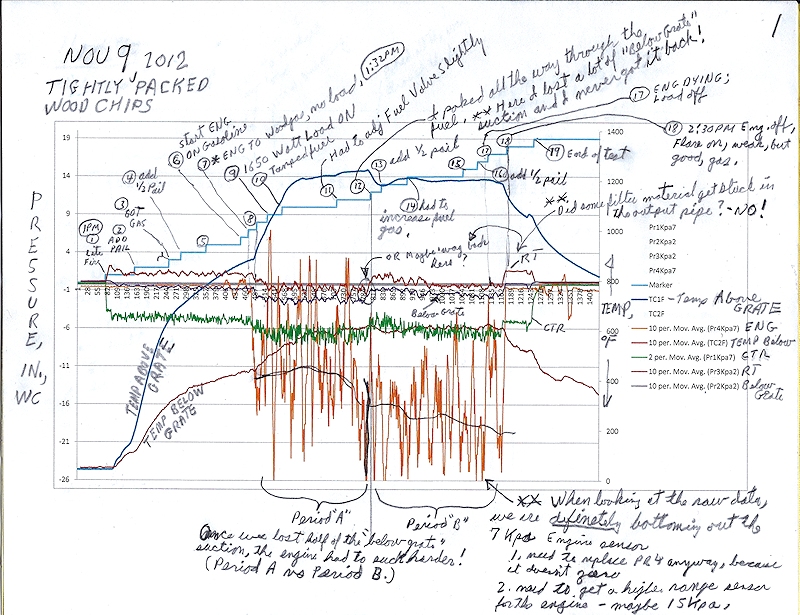

Here are two graphs of the run.

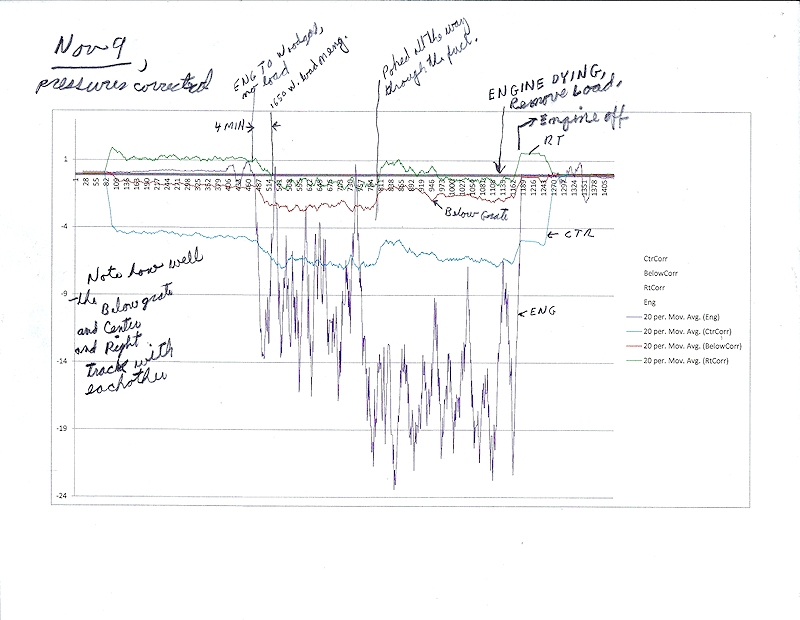

This graph has lots of information on it. I pencilled in the important points of the run.

The pressure data is all "raw" data. That is: the sensors were not zeroed out before the test began.

-Note that the pressure plots on THIS graph are moving averages of the last 10 readings.

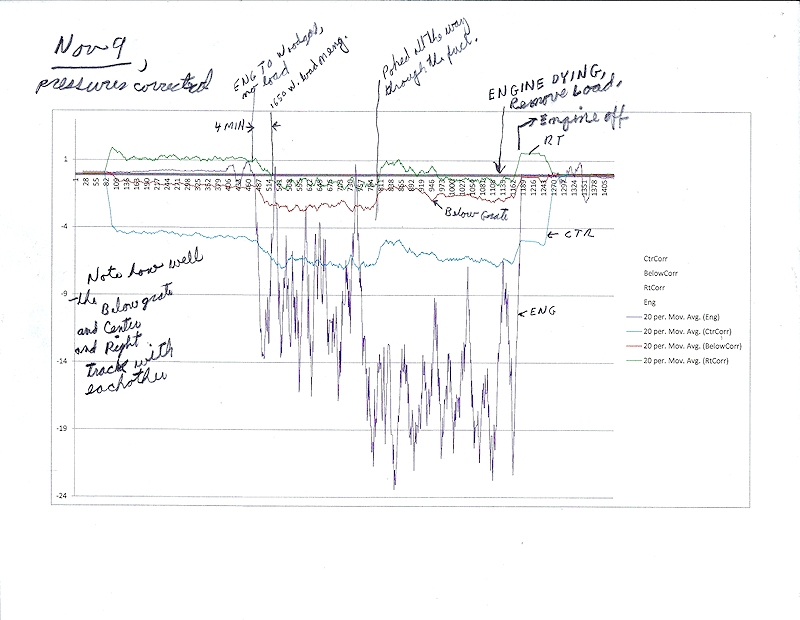

Here is the same period of data with both temperatures and the marker removed, and with much less of my hen-scratchings. I corrected all the pressures on my spreadsheet, so all the

data are as accurate as they will ever be.

-Note that the pressure plots on THIS graph are moving averages of the last 20 readings.