During the construction of my Medieval Domed Metal Chest, I needed a lot of rivets. Most of them were 1/16" diameter.

I made many of

them from soft 16 gage wire, and I also bought some small packages of 1/16" diameter rivets for some uses.

But, in several places, we needed larger rivets so Tom Latane' suggested using common hardware store nails as the source.

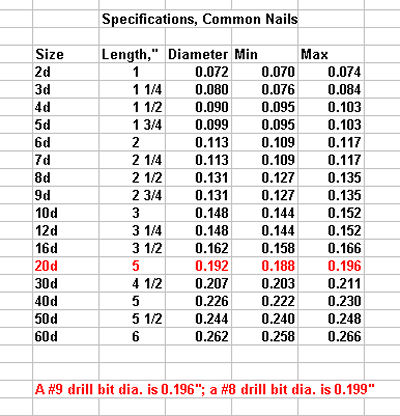

Here, I simply present a table of common nail sizes so you can see the wide variety of rivets that can be produced from

them.

When choosing a rivet size, you also need to have a table of drill bit sizes handy, so you can match the hole to the rivet.

In general, I'd suggest making the hole no larger than 2 or 3 thousandths of an inch bigger than the rivet. An easy "sliding"

fit, but not a loose fit.

I am in the USA, so I will talk in terms we use here:

You should have drill bit tables for fractions, numbers and letters available.

You can see from the center table, the one that has the diameter listed, that these nails can make rivets as small as just

over 1/16" diameter to just over 1/4" diameter.

Note the tolerances listed for each size. You will have to take this into account to accurately choose the best drill bit to use.

Example: We needed hinge pins for the chest. Tom suggested making the hinge pins from 20D nails.

I measured some of them and they were all very close to the 0.192 inch diameter number that is in the middle of the tolerance

band. So, since I wanted a somewhat looser fit than for a rivet, I looked up drill bit sizes in that range.

At the bottom of the table, you can see my choices.

I chose the #9 drill bit, which is 4 thousandths bigger than the nail.

By the way, as I am sure you all know, a drill bit always drills a slightly bigger hole that its own diameter, and a poorly sharpened drill bit makes an even bigger hole.

To make the rivet:

Sometimes I use the nail's head as the head for the rivet, but that's when the head will be hidden and/or the application

isn't decorative. Also, the ridges up close to the head, that the heading machine makes, can make it hard to get a good

fit. So, when a good fit is required, I cut the head and the ridged part off the nail and use only the shank. Then I make

my own head, cut the rivet to length and then cold head the other end in place.

A couple of caveats:

-Don't use hardened nails (like masonry nails)

-There are other tables of nails size out there on the web, but this one seems to fit the nails I get at the local hardware

stores. So, a dial caliper would seem to be a good investment to make certain that things fit properly.