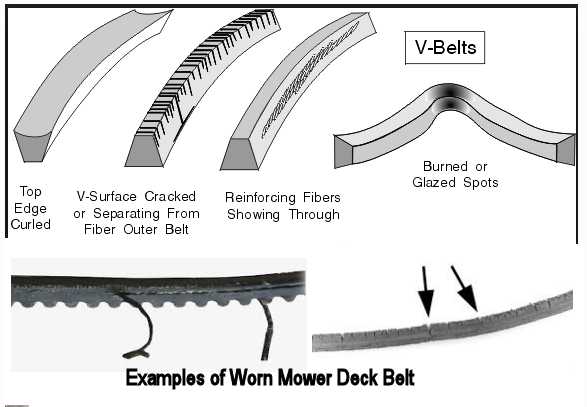

Here are some signs of belt wear:

If you see ANY signs of wear such as the above, then the belt needs to be replaced before proceeding.

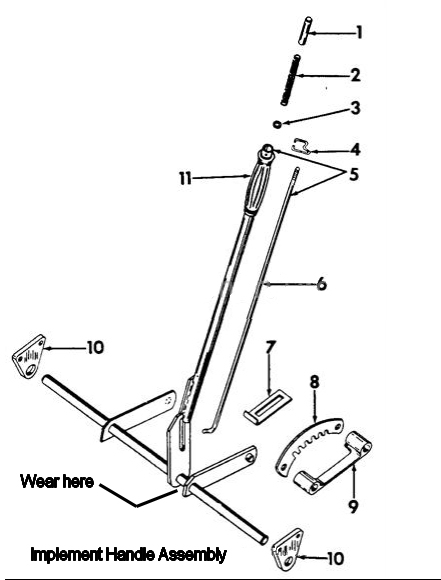

If the problem started all of a sudden after you have just removed and replaced the deck, it may be that you didn't get the "fork" (on the end of item 17) in the article below properly located around the Implement Handle Assembly's pivot shaft. Read on and you will see what to do.

---Assuming that you have already checked for loose brackets or links that have come loose---

The problem is that the deck lifting mechanism has a serious wear point that allows the deck to droop in the front.

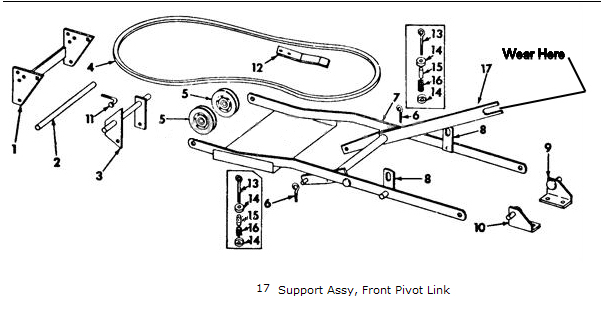

If you examine the deck and the "mule" (see the picture below-- its the attachment device that the deck hangs from),

you will see how the lifting lever assembly pulls the deck upward as the lifting lever is pulled toward the rear of the machine.

Note that there is a "fork" shaped piece down there (item 17 in the picture below) that slides over the shaft of the Implement Handle Assembly. (That shaft also supports the foot boards).

The lower side of that fork wears badly, sometimes so much that half of it is worn away.

This is part of the cause of the deck drooping.

In addition, the underside of the shaft that the fork rubs on also gets worn away by the fork.

Sometimes it is almost "sawn" all the way through on the bottom side.

The reason for the wear is that, as the deck bounces up and down as the machine moves over the ground, the fork is constantly rubbing back and forth on the shaft. Maybe a poor design, but it appears to take 20 or 30 years to become a problem.