Delta 28-560 16" Bandsaw, Reviving One

Created: October 27, 2020

Last Revised: October 18, 2023

French Creek Valley Home

Back to My Woodshop

Blacksmithing

Contact Us

16" 3 Wheel Delta 28-560 band saw revival

Just a general note about this bandsaw: I found several negative comments about this 28-560 model of Delta bandsaw out on the web

as I was preparing to get mine going.

The comments were usually from people who didn't actually own one. But I also found positive comments from owners, too.

For my part, I like the saw and it is running just fine for me. I have had NO problems with blade tracking, by the way.

Status of the saw on September 22, 2020:

The bandsaw is completely up and running as of today, using the new saw blade that I just installed.

Youtube Video showing how this Delta 28-560 looks and works now

Background and log of the process:

I bought this saw on August 10, 2020 from a Smith Sales auction for about $14.00 in non-running condition.

Aug. 25, 2020: Status of the saw, now that it is running:

The saw works and all major issues have been resolved.

About all that's left is that the saw bogs down in the cut when I try to turn corners with the 1/4" X .016" thick blade that came with it. I think the reason is that there is NO set to its teeth at ALL.

Today I ordered two new blades; a 3/16 X.025 X 10 tpi and and a 3/8 X .025 X 6 tpi.

Some folks say the .025 blades will be okay and some say they break more often because of the "smaller" diameter (8") wheels on this saw.

I don't see that as a problem since I have been using .025 blades in my 7" wheel 4 X 6 metal cutting bandsaw for 30+ years without breaking any.

Yesterday, I ordered a "universal tool stand" for it from Harbor Freight.

The upper surface of that stand is wide enough, but the length is a bit too short for the saw, so I will have to make a (wooden) top to mount it on.

Original issues with the saw:

1. The Motor was almost stuck. (Wouldn't run at all) It's a 1/2 hp 1725 rpm model with 1/2" output shaft.

-Spent several hours trying to figure out why. Shaft and bushings look great. But somebody had been in there before me.

finally had to ream rear bushing by a few thou to get it to work.

2. It came with only one blade that had NO set left.

-Blade length is supposed to be 82 inches. The one that came with the saw seems to be 79 inches long.

3. Miter gauge missing.

-I found a substitute that fits.

4. Rip Fence and rip fence support bracket missing.

-I don't really need one. Besides, when it's in place, it has to be removed to change blades anyway.

5.Upper Blade Guide Clamp broken

- I made a new one with a slightly different, but stronger design. Made one slight miscalculation,

so I had to add short piece of 1/4" square stock to shim it to get it to work. Shouldn't be an operational problem, though.

I may have to glue the shim in place at a later date.

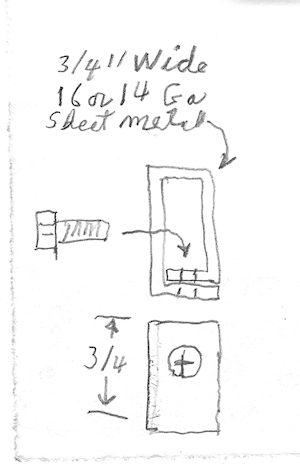

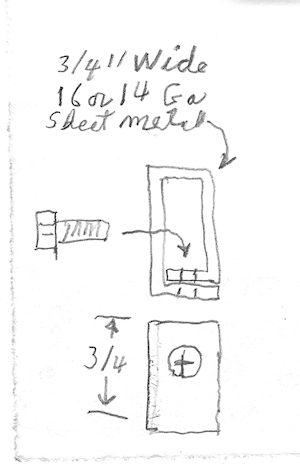

Here's a sketch of the clamp that I made.

I cut a 3/4" wide strip of 16 gage sheet metal 6 0r 8 inches long, then formed it into an overlapping rectangle

(cutting off the excess) as shown in my sketch. I made the inside width just wide enough to fit the head of a 3/8-16 bolt

that was about an inch long. The length of the slot is just long enough to capture the guide and the head of the bolt.

6. Drive belt broken

-Ordered a new one from Ebay seller "polybelt".

I hadn't realized that the saw had a high speed (large) drive pulley for wood and a small severely crowned low speed pulley on the motor's

shaft at the center of the large one, for metal. Not realizing that, I ordered the shorter "metal" belt instead of the longer "wood" belt.

I didn't know about that "metal" pulley, so I thought I had simply gotten the wrong one.

I called the seller and they set me straight. Right after that, I googled around and found the owner's manual; a thing I should

have done before I even bid on the machine.

7. Tires badly cracked and loose on the wheels.

They don't show signs of ever having been glued on.

-I have now ordered a "set" of polybelts: One metal drive belt, one wood drive belt and two tires.

Apparently the tires simply stretch over the driven wheels and are NOT glued on.

-Aug 24: I received and installed the new tires and the "wood" drive belt.

I had to use 3 C clamps to hold about half of the tire in place while stretching the rest of it onto the wheel.

The instructions that came with the tires said to place them in really hot, soapy water so they'd go on easier.

They also sent a small screwdriver that had a piece of sleeving on it to help coax the tire onto the wheel.

The drive belt went on with a little less effort.

-After that, I installed the blade that came with the saw, made some tracking adjustments and got it running.

8. Table support (protractor-looking) brackets: The front one is badly bent and one of its two mounting bolts is even bent!

The rear one is bent slightly. (Saw must have been dropped or tipped over?)

-I spent considerable time straightening that bracket and filing the curving slot so the table could be easily tilted. Replaced the bent bolt.

9. Table casting is slightly bent.

-I have seen this same problem on a youtube video of another of these saws. The right side of the table sits slightly below the left side at the front.

But, right at the throat of the table, there is no problem at all. I might be able to shim one of the table support brackets to push the low

side into line. I see this as a pretty minor problem.

10. Table tilt angle slightly off.

-Adjusted table tilt stop per the manual.

,br>

11. Table is tilted a few degrees front-to-back.

Not sure how this could happen, but maybe from my work in fixing the "front" protractor bracket. I wonder if the saw had been knocked over

or dropped at some point.

- I removed the bolts from the rear table support bracket and shimmed it upwards with two flat washers to eliminate the slope.

12. The circular Table Insert that supports work right around the blade is missing.

-I made a new one from .092 aluminum sheet.

13. Table was very rusty

-Wire wheeled it and followed up with 180 sandpaper.

Polished it with chrome cleaner and then Johnson's paste wax.

14. No Stand. This, of course, is not a "problem with the saw", but it's a feature I'd like to add:

Feet: The saw sits on two 12" long stamped sheet metal "feet". This makes its footprint 12 inches wide by 24 inches long.

I have now installed the Harbor Freight floor stand so now it even has a shelf under the saw to store stuff on.

In closing, I want to reiterate that this bandsaw is working just fine for me.

I have received the new blades that I mentioned above and had no trouble at all in getting them to track.br>